30 YEARS OF EXPERIENCE IN

INSPECTION TECHNOLOGY OF CONVEYOR BELT

Sentechnics Co., Ltd.

Add: 28 Dongfeng Rd., Taiyuan, Shanxi, China, 030013

Tel:+86 351-6378060

Fax:+86 351-6378061

Email: bernd.kuesel@cbguard.de

PRODUCT OUTLINE

As the main components in lifting and transportation

equipment, steel wire ropes are widely used in mines, metallurgy, ports,

wharfs, elevators, etc. However, in the course of long-term use, wire ropes,

corrosion and other damages often occur, such as not found in time, which will

have serious consequences for safe production.

Wire rope breakage accidents have occurred from time

to time. According to the statistics of the State Administration of Work

Safety, in recent years, there have been as many as 1,065 rope breaks in

China's coal system, including the most serious rope breaks and 20 deaths.

For a long time, people have used manual visual

inspection and regular replacement of steel wire ropes to avoid accidents.

However, the manual visual measurement method has poor reliability and low

efficiency, and regular replacement causes huge waste. According to statistics,

more than 70% of the replaced wire ropes have little or no loss of strength. As

long as it is running, the safety of the wire rope is always a "line"

- even if it runs for 1000 hours without failure, there is no guarantee that

the next hour will be safe and reliable; even if it looks intact, it will not

guarantee absolute safety; even if it is completely adopted new ropes may also

be insecure due to quality defects.

Due to the complexity of its own structure, the

diversity of the operating environment and the limitations of the detection

methods, a large number of wire ropes do not have good safety guarantees, and

together reflect the three major contradictions of "hidden danger, waste,

inefficiency".

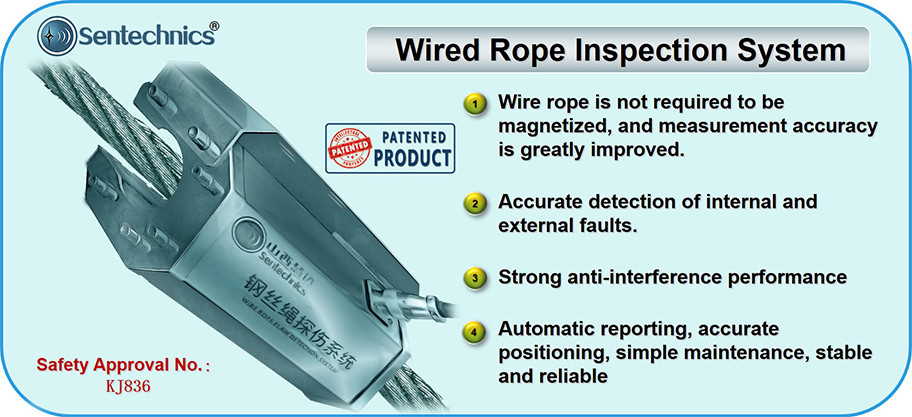

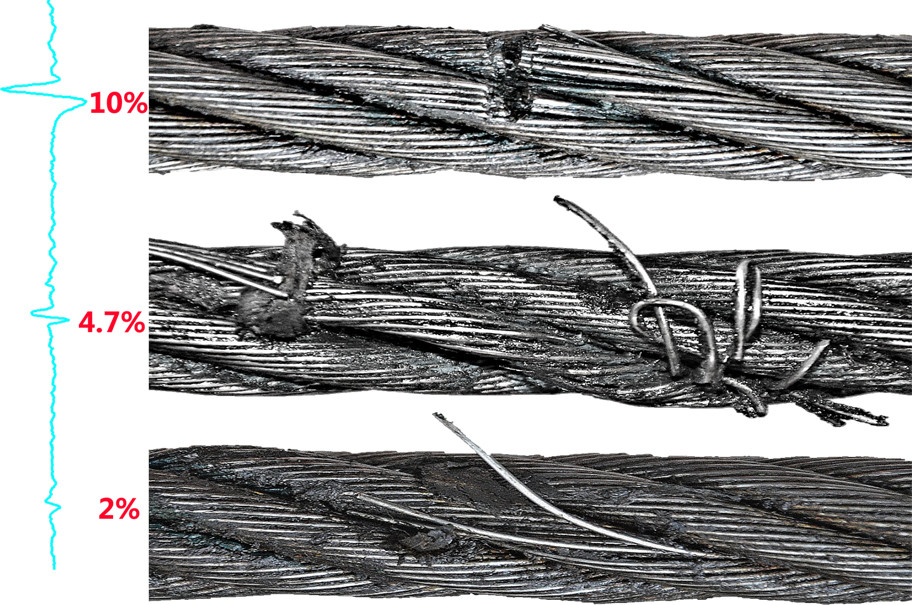

Our company adopts the new generation wire rope

defect measurement method-flux balance measurement principle, its measurement

sensitivity is extremely high, and it can effectively overcome the influence of

wire rope jitter on measurement accuracy, and can effectively detect the inner

and outer broken wires of steel wire rope.

PRODUCT NAME AND MODEL

Wire rope flaw detection system for coal mine, coal

safety model: Kj836

BENEFITS

Improve safety: Through real-time detection of wire

rope internal and external broken wire, rust, wear, local enlargement of the

rope neck, flattening, twisting, bending and other hidden dangers, users can

fully understand the safety status of the wire rope in real time, and know

whether the wire rope is safe or not. Timely detection of problems, timely

repair or replacement, eliminating the hidden dangers of sudden wire break

accidents from the root cause.

Improve economic efficiency: It can significantly

extend the service life of steel wire ropes, and can continue to use it while

fully understanding the safety condition of steel wire ropes, thus avoiding the

early change of ropes due to unclear situation and worry about the hidden

danger of wire ropes. At the same time, the automation of wire rope daily

inspection is realized, and the production efficiency of the enterprise is

improved.

COMPONENTS

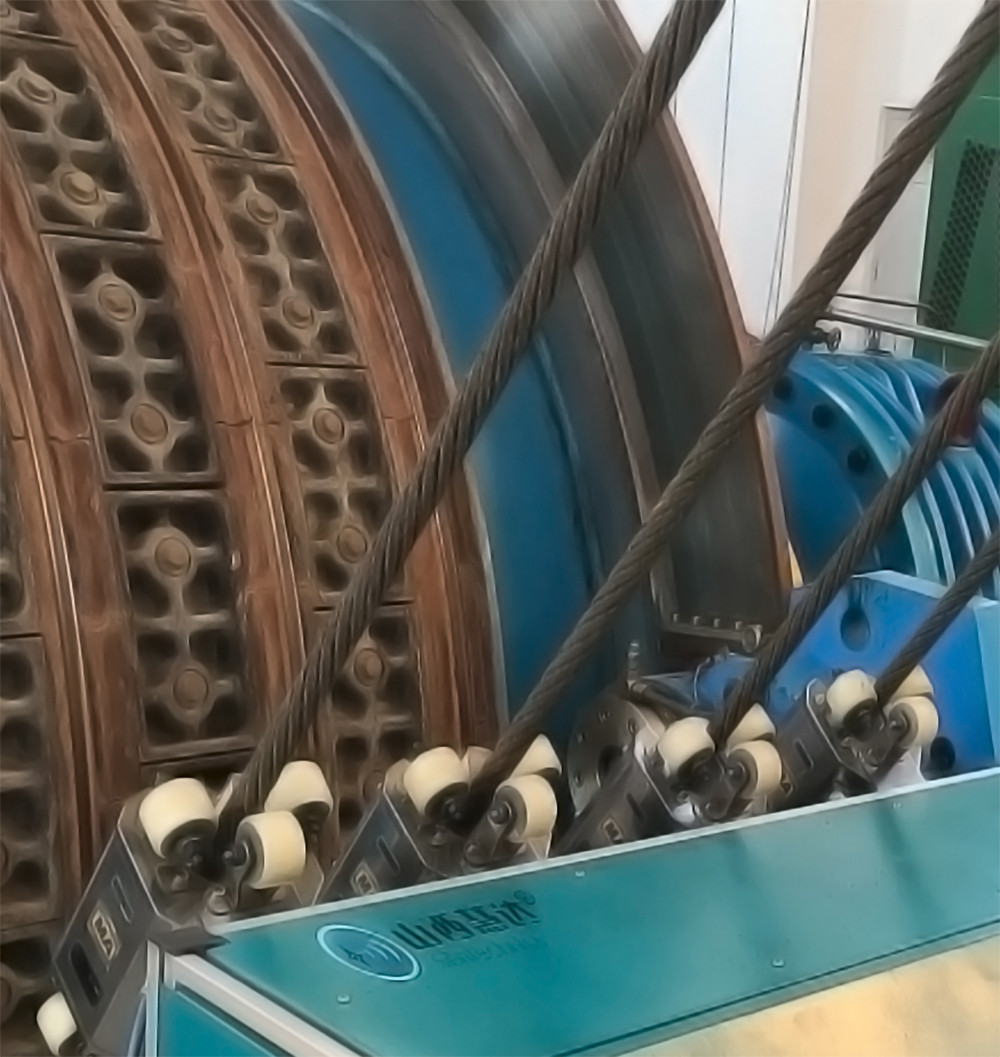

Mine intrinsically safe wire rope testing sensor,

mine explosion-proof and intrinsically safe information substation, industrial

computer, etc.

APPLICATIONS

Widely used in mines, ports, oil, electricity,

lifting machinery, ropeways, elevators and many other wire rope applications.

Non-destructive testing of ferromagnetic wire ropes of various categories and

specifications is possible. For example, mining winches, mining hoists, mining

overhead manned devices (monkey cars), cable cars, etc. Customized products for

specific environments and more personalized features can be tailored to the

specific requirements of the customer.

Product Category

There are fixed online wire rope detecting devices

and hand-held wire rope detecting devices according to the use form; single

rope, double rope, 4 rope, and 6 rope type are classified according to the

number of steel ropes; and vary depending on the diameter range of the steel

wire rope.

Installation and use

The installation is quick and easy, and the

installation position is generally selected in the area where the wire rope is

not seriously shaken and is easily accessible. The software interface is simple

and friendly. Users only need to click “Start Detection”, the system will

automatically detect and automatically generate reports. All damages and defects

are listed in the report.

Copyright © 2006 - 2025 Sentechnics All Rights Reserved