30 YEARS OF EXPERIENCE IN

INSPECTION TECHNOLOGY OF CONVEYOR BELT

Sentechnics Co., Ltd.

Add: 28 Dongfeng Rd., Taiyuan, Shanxi, China, 030013

Tel:+86 351-6378060

Fax:+86 351-6378061

Email: bernd.kuesel@cbguard.de

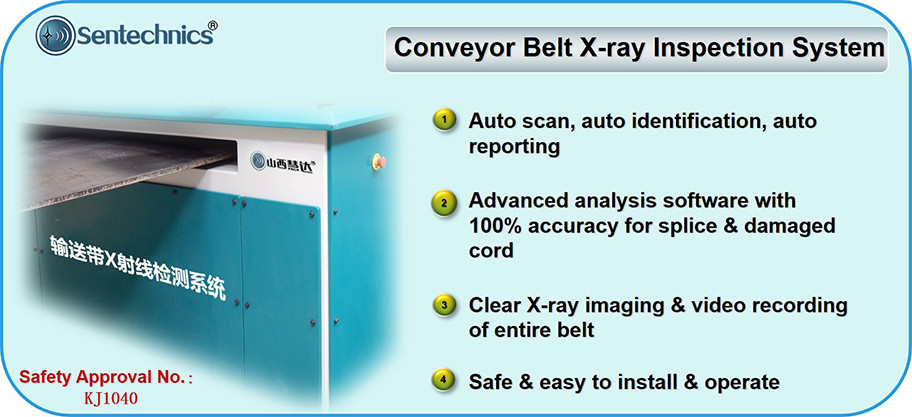

PRODUCT OUTLINE

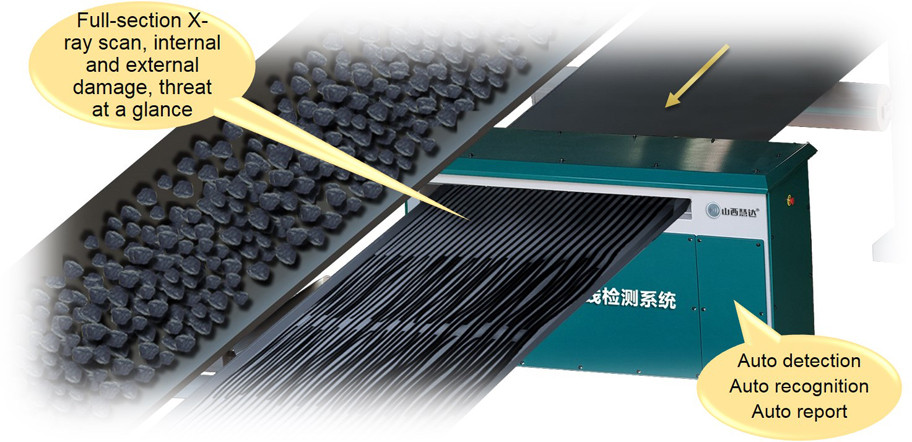

Sentechnics' X-ray inspection system is a highly automated and intelligent conveyor belt detection system with automatic scanning, automatic intelligent identification, automatic reporting and automatic warning. So far, it is the most advanced X-ray conveyor belt in the world.

SAFETY APPROVAL NO.

RADIATION SAFETY APPROVAL NO.

(JFA)02159

1. Significantly improve safety level

2. Significantly reduce operation cost

FEATURES

Real-time online monitoring: full-section, real-time scanning, real-time imaging, real-time intelligent identification of all hidden threats.

Real-time display: Intuitive real-time display of full conveyor running status.

Fully automatic intelligent analysis software: software automatically completes the steel cord damage (decapitation, twisting, blasting, rust, wire rope spacing, etc.); cover damage (edge damage, rubber cover thickness change, rubber cover wear, scraping, perforations, voids, insertion of foreign objects, material accumulation, etc.); splice damage (excess movement of steel cords within splices), belt deviation, belt width change, belt speed change, etc.

Automatic report: Once a complete revolution inspection is automatically done, the software automatically sorts out each fault image, fault location, fault size and other information identified during the inspection, and automatically generates a graphic report.

Simple operation: very friendly interface, the user just needs one-click operation to complete the detection and analysis. Spend just a few minutes to read the automatically generated report to know exactly if the belt is safe? What are the problems? How to fix it?

Remote operation: The operator can perform full-featured operation away from the field scanner installation location.

Dynamic database: All identified threats of the entire conveyor belt are stored ina dynamic database. The conveyor belt state is clear at a glance. Customers can choose a magnifying glass to view any details.

Fault Location: Accurately positioning for each identified fault. All location information is displayed in the observation window and report.

Unattended operation: The entire inspection process can be completed automatically according to the set time period, without the need for personnel to guard at site.

Data sharing: Data sharing is realized through the LAN. Users can view the entire belt running status on any compute through Ethernet/fiber communication.

Radiation safety: This system uses artificial X-rays and does not contain any natural radioactive materials. The system does not generate any radiation once the source is turned off. This system uses multi-level security measures to ensure 100% safety, whether used correctly or misused.

INSTALLATION & OPERATION

The system is divided into on-site inspection

equipment (the scanner) and remote controloperation equipment(computer).

Remote equipment (host computer and ground optical transceiver) are generally

installed in the ground monitoring room; field devices (scanner) are generally

installed in the position where the belt is flat close to the conveyor head.

The video image receiving board and the X-ray generator are respectively fixed

on upper and lower side of the return belt, and are connected to the ground remote

computer through optical cable.

Installation is simple and quick, and almost all conveyor systems meet the space requirements without the need for additional facilities. Once installed, the database can be set up once, unless the customer's conveyor belt changes (such as adding or removing splices, etc.). No professional operation, no regular calibration, no routine maintenance, no external environmental interference.

QUALITY & SAFETY

All mining products have passed the coal mining safety approval, and have coal mining safety certificate and explosion-proof safety certificate; X-ray inspection products have radiation safety certification issued by the government. Sentechnics provides lifelong service, software lifelong upgrade, lifetime remote diagnosis service.

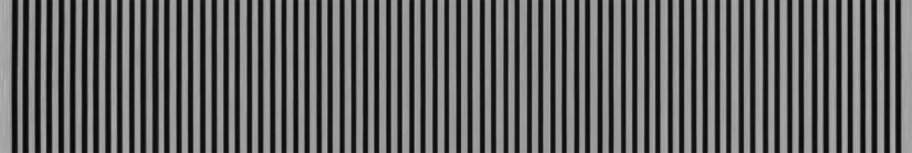

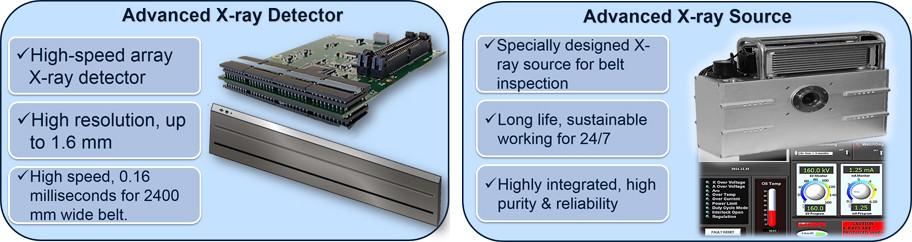

1. Advanced X-ray source

It is customized by VJ Technology Co., Ltd. (modular X-ray source) to ensure the best image quality, small size with excellent performance and high reliability. Main performance indicators can be adjusted with the application environment. Revolutionary innovations in X-ray intensity and direction have solved the problem of uneven distribution of background gray scale.

2. Leading high-integration multi-channel signal acquisition system —intrinsically safe X-ray receiver

The detector uses a highly integrated multi-channel signal acquisition system (DH system) with leading technology, which combines coal mining safety reliability and performance excellence. The acquisition system converts the optical signal obtained by the detector into a digital electrical signal. The high-precision A/D conversion system enables seamless photography.

From the initial design of this product, Sentechnics fully considers the X-ray radiation characteristics and international standards, and adopts strict safety protection measures to ensure the safety of operation and maintenance personnel under any circumstances. When the X-ray source is turned on and reaches its maximum energy, the dose at the safety fence is ≤ 1 μSV/h, which is fully in line with international standards.

Using the world's advanced face recognition and palmprint recognition algorithms, developed a fully automation inspection system with automatic scanning, automatic recognition and automatic report.

Copyright © 2006 - 2025 Sentechnics All Rights Reserved